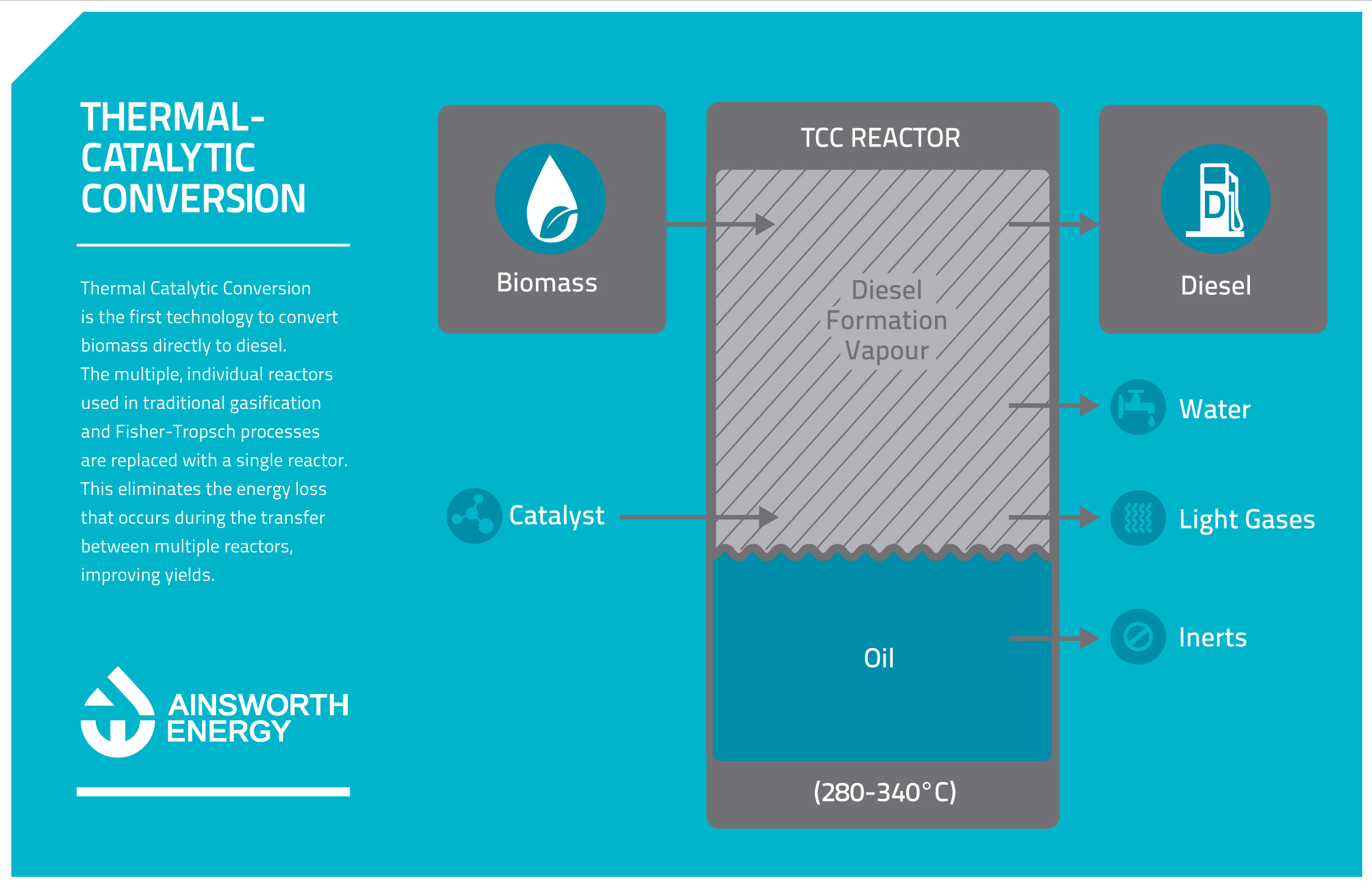

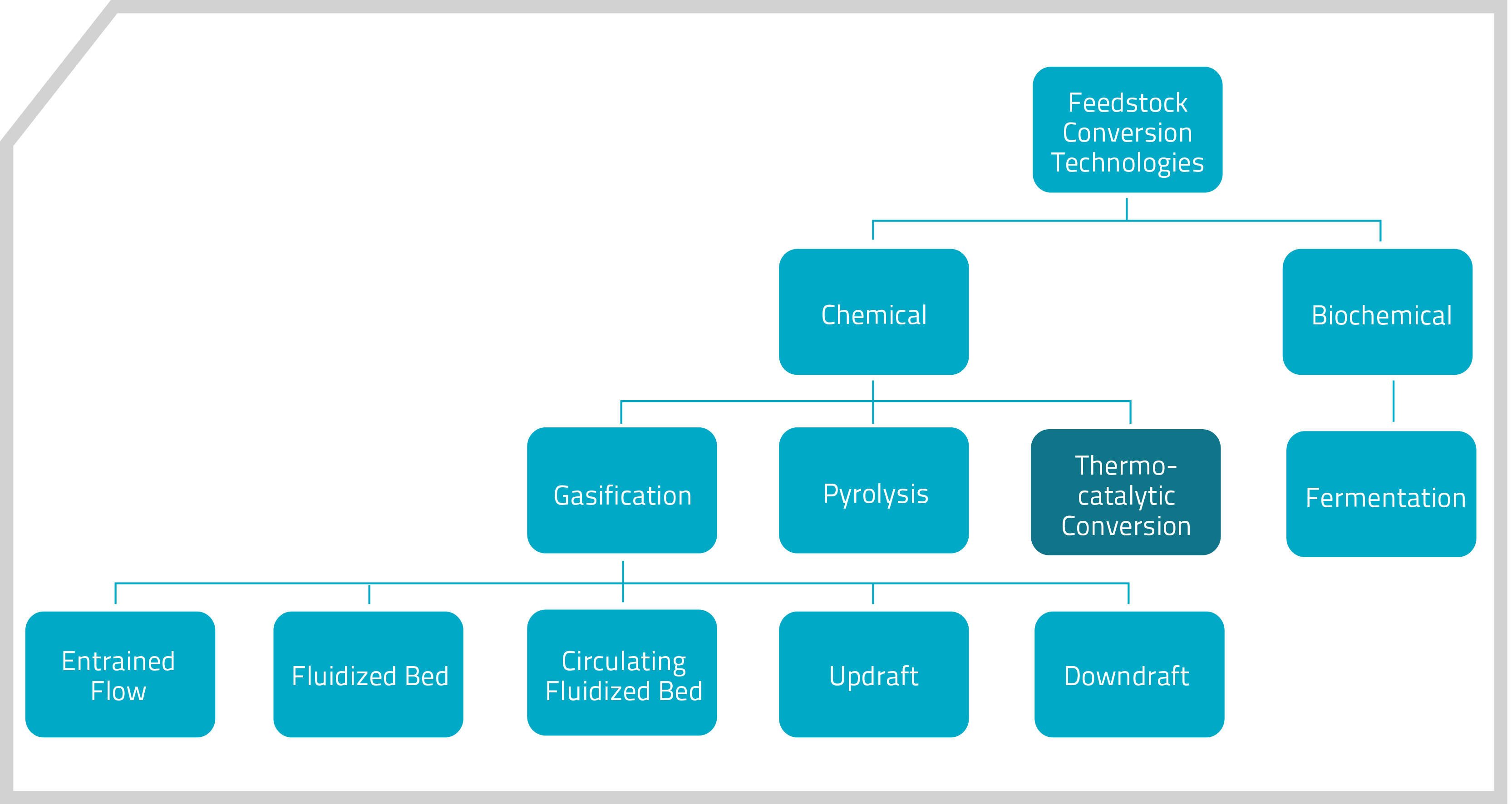

Thermocatalytic conversion (TCC) system uses a catalyst and thermal oil as a heating medium to convert biomass directly into a drop-in diesel fuel that meets ASTM D975 Ultra-Low Sulphur Diesel (ULSD) standards. Lightweight hydrocarbons, a by-product, can be combusted to generate thermal heat and/or electricity. Consequently, this technology produces two high-margin products with low operating costs.

TCC can be operated without an external energy supply as the process generates sufficient energy to supply 100% of its power requirements with excess that can be sold.

Unlike many emerging technologies, or concept fuels, TCC systems have already passed laboratory programs and have been proven in a small commercial-scale facility. Attractive yields can be achieved using a number of feedstock options, including livestock manure, wood waste, municipal waste, and end-of-life plastics.

In contrast to all other biomass-to-liquid fuel (BtL) processes, which require multiple reactors to refine their output to useable diesel, TCC systems nest the chemical reactions into a single reactor, eliminating energy loss that occurs during the transfer of energy between reactors. As a consequence, the capital cost of these plants is significantly reduced.

Advantages of TCC systems:

- Safe, closed process and energy loop

- Single step conversion mode (converts biomass directly to ULSD; no additional refining)

- High yields are produced from a wide variety of feedstock sources

- Diesel is produced at a competitive cost; even without subsidies

- It produces low cost surplus electricity as a by-product

- Qualifies for compliance units (CU) in Canada & RIN (diesel) in the US and REC (electricity) with appropriate feedstocks

- No unlawful emissions, no harmful by-products and no environmentally harmful residues are produced

- Electrically self-sufficient